PU fiberglass pultrusion knowhow

LEADING IN TECHNOLOGY--CONTINUOUS PULTRUED COMPOSITE SYSTEM

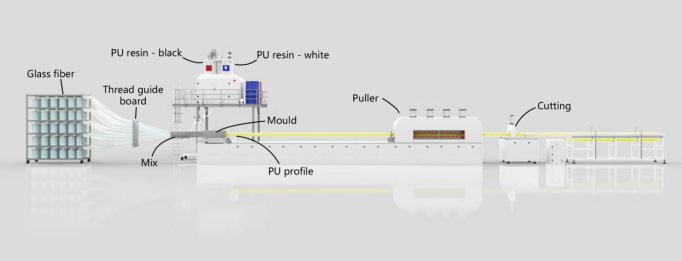

The continuous pultrusion composite material system is a manufacturing process used to produce continuous lengths offiber-reinforced polymer (FRP) composites.

The process involves pulling continuous fibers (usually glass,carbon,or aramid fibers) through a resin bath to impregnatethem with thermosetting or thermoplastic resin.The impregnated fibers are then guided through a heated die,where the resin cures and shapes into the desired form, creatinga rigid, strong, and lightweight composite profile.

The production of polyurethane composite profiles involves introducing glass fibers into a mold through a guide plate, and injecting AB component polyurethane resin into an injection box through a glue injection machine. The resin is then heated and cured in the mold, and the product is pulled into shape by a front-end traction machine. The entire process is called pultrusion technology.

- Previous article:Pultrusion knowhow service

- Next:There is no more.;

+86-13761919721 / +86-13585804232 / +86-13788973468

+86-13761919721 / +86-13585804232 / +86-13788973468